The Journey of Milk: From Farm to Fridge

The journey of milk from the farm to your table is a fascinating and intricate process that many may not fully appreciate. Milk is not merely a simple liquid; it undergoes various transformations and travels considerable distances before reaching the consumer. In fact, once milk is collected from dairy cows, it embarks on a journey that takes it through processing plants, transportation networks, and finally into retail outlets, where it is purchased by consumers. Understanding this journey reveals the dedication and effort that goes into producing a staple found in households around the world.

Upon leaving the dairy farm, milk is immediately cooled to ensure its freshness and to inhibit the growth of bacteria. This rapid cooling is crucial, as it preserves the quality and safety of the milk throughout its journey. If left at ambient temperatures, milk can spoil quickly, potentially leading to health risks for consumers. Following this cooling process, the milk is transported to a processing facility in large refrigerated tanks. Here, it undergoes pasteurization, a key step that involves heating the liquid to a specific temperature for a set period. This process is critical in killing harmful bacteria such as Salmonella and E. coli, ensuring that the milk is safe for public consumption.

The Role of Packaging in Milk Preservation

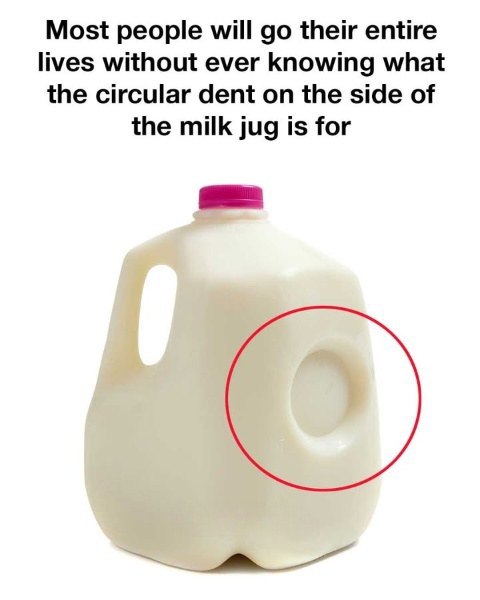

Once pasteurization is complete, milk is packaged into bottles or jugs designed to maintain its freshness and safety. One common yet crucial feature of these containers is the small circular indentation often found on the side of the jug. This seemingly minor design element plays a significant role in managing internal pressure during transportation and storage. As milk is transported, it is subject to temperature fluctuations that cause the liquid to expand and contract. The indentation acts as a flexible pressure valve, allowing the jug to accommodate these changes without the risk of bursting or leaking, thereby protecting the product and maintaining its quality.

When the milk warms up during transport, the liquid expands, and instead of forcing the jug to stretch, the indentation bulges outward. Conversely, when the temperature drops and the milk contracts, the indentation returns to its original position. This silent yet crucial functionality allows the container to withstand the stresses of movement and temperature changes, ensuring that the milk arrives at the store intact and safe for consumption. Without such design considerations, consumers could risk purchasing spoiled milk or encountering leaks during transportation.

Durability Through Design

The design of milk containers is not just about managing pressure; it also enhances durability. Milk jugs frequently endure bumps and drops during transport, whether in trucks or during handling at grocery stores. The circular indentation provides structural integrity, functioning like a shock absorber that distributes the force from an impact. This means that the jug is less likely to crack when it encounters a hard surface, such as a shopping cart or the floor of a store. Such durability is essential not only for ensuring product safety but also for minimizing waste due to damaged products.

By employing a simple geometric shape to enhance the jug’s strength, manufacturers can reduce the amount of plastic used without compromising on durability. This innovative design solution not only saves costs for producers but is also beneficial for the environment by reducing plastic waste. In an era where sustainability is paramount, a small indentation effectively performs the work of thicker materials, showcasing how thoughtful design can lead to eco-friendly practices. This balance between cost-efficiency and environmental responsibility is a hallmark of modern product design.

Warning Signals and Consumer Safety

Another critical aspect of this design feature is its function as an early warning system for consumers. When milk begins to spoil, bacteria produce gases that increase the pressure inside the container. The circular indentation reacts to this change; if the milk is going bad, the dent will bulge outward and remain puffed. This visual cue serves as an important indicator that the milk may no longer be safe to drink, prompting consumers to inspect the product before use. This consideration for consumer safety extends beyond mere packaging, encouraging individuals to be more vigilant about the products they consume.Though not a foolproof method for determining spoilage, the bulging dent provides an accessible and immediate warning to consumers. This feature encourages caution and ensures that individuals are more informed about the state of their milk before consumption. This proactive design element represents a thoughtful consideration for public health, merging safety with usability. It empowers consumers to make informed choices, ultimately promoting healthier eating habits.

A Symphony of Design Features

In addition to the pressure management system, many other design elements of a milk jug contribute to user experience. The handle is ergonomically shaped for easy pouring, minimizing spills and waste, while ridges in the base improve stability, preventing accidental tipping. Additionally, color-coded caps indicate the fat content of the milk, allowing consumers to make informed choices based on their dietary preferences. For example, a red cap may signify whole milk, while a blue cap is often used for reduced-fat options. When viewed collectively, these features demonstrate that a simple milk jug is, in fact, a culmination of practical and innovative design principles. Every element, from the shape of the handle to the flexible pressure valve, has been meticulously crafted to ensure that milk remains fresh and safe while also providing convenience for the consumer. This careful attention to detail makes everyday products like milk jugs exemplary models of modern engineering and design. The thoughtful integration of functionality and aesthetics exemplifies how design can enhance everyday experiences.In conclusion, the journey of milk from farm to fridge is not merely a logistical endeavor; it represents a remarkable intersection of science, engineering, and thoughtful design. Each step of this journey, from pasteurization to packaging, plays a crucial role in ensuring that the milk you pour into your glass remains safe and delicious. The next time you reach for a carton of milk, take a moment to appreciate the intricate and well-designed features that protect this beloved liquid and enhance your enjoyment of it. By understanding this journey, consumers can develop a greater appreciation for the complexities involved in bringing this nutritious product to their tables, fostering a deeper connection to the food they consume.